Typically slewing ring bearings are used in excavators crane wind power turbine and other oscillating service.

Slew ring grease.

When begin use it the user should fill into full new grease which could make sure the slewing bearing works in good function.

When filling grease slowly turn the slewing ring to make the grease fill evenly.

In slewing ring bearings a heavy duty extreme pressure grease is required.

The slewing rings are essentially working in fatigue.

Watch his brief video and learn from jeff payne caterpillar maintenance expert how to maintain the swing bearing and swing gear on your cat hydraulic exca.

Fill in the slewing bearing grease.

Inadequate lubrication is the most common cause of premature bearing failures.

More than 96 of slewing ring failure could be avoided by following simple maintenance tips.

Lubrication is especially important in the maintenance of slewing bearings.

In case of some slewing ring bearings fatigue may occur due to improper internal lubrication.

Later fine cracks develop followed by flaking.

The grease must entirely cover the flanks of the pinion and of the ring gear whether applying by brush or spraying.

When lubrication is inadequate surface damage in the form of roughening or waviness occurs.

We recommend retightening the fasteners after the first two to four months of utilization and then proceeding to a systematic yearly check.

This video shows how i got access to the 360 degree slew gear ring on a jcb micro digger it was found to be lacking grease and covered in dirt i was the.

Before deliver from the factory the slewing bearing is filled with a small amount of ep ii.

Slewing bearing is normally used ep ii extreme pressure ii lithium ester.

New grease must be added before and after the machine has been shut down for a long time.

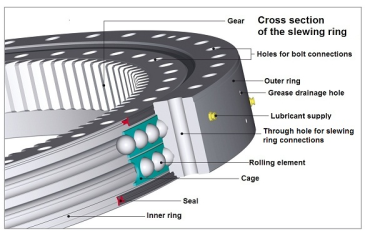

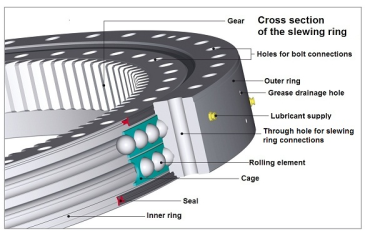

Consisting of rings mounted with threaded fasteners and usually having a gear integral with one of the rings.

Apply a liberal shot of extreme pressure grease to the fittings around the bearing s circumference at intervals recommended in the operator s manual.